How Gin is Made

September 11, 2020

Gin is arguably the best-liked spirit in the UK. One-in-three Brits names the drink as their favourite spirit – but how many of us actually know how gin is made?

As makers of IWSC awarded gins, we like to think we know a thing or two about the gin-making process. In this article, we’ll guide you through how gin is made, from grain and garden to the cocktail glass. Pour yourself a G&T, and let’s talk stills, washes and botanicals.

Making the base spirit

The first step in making gin is to make a base spirit, very much akin to vodka. This is done by fermenting a raw ingredient that contains sugar, and then distilling the resulting liquid to increase its alcohol content.

We start by selecting the raw ingredient that will be used to make the spirit – usually a type of grain. At Wild Knight Distillery, we use barley from our local region. Other grains commonly used to make the base spirit for gin include wheat and corn. The choice of grain will define the flavour profile of the base spirit, so a good distiller chooses carefully. Premium gins are often made with locally sourced grains, which can give the spirit a distinct character and provenance.

Once a grain has been chosen, we can prepare it for fermentation. The milled grain is steeped in hot water to create a mash that converts starch to fermentable sugars. Once this process is completed the liquid is separated from the grains and cooled to allow the distillers yeast to be added. The yeast metabolises the sugar from the grain, producing ethanol and other alcohols as by-products. At the end of this process, we are left with a moderately alcoholic liquid called fermented wash. The wash is then distilled until a strongly alcoholic, high-purity, vodka-like base spirit is created. Finally, the base spirit is reduced down until it reaches an ABV of around 50%, ready for redistillation.

Adding flavours through redistillation

Now, here’s where we turn our base spirit into gin.

All gins are flavoured with one or more plant-derived ingredients, through a process of steeping and redistillation. The ingredients are often referred to as botanicals. Every true gin contains juniper, the berry-like female seed cones produced by various species of juniper tree. Juniper gave its name to jenever, the Dutch spirit from which gin was adapted. If a spirit doesn’t contain juniper in sufficient volumes, it cannot be called a gin.

The other botanicals added for steeping and redistillation can transform a spirit’s flavour. Widely used gin-making botanicals include coriander, cardamom, cinnamon, lime and grapefruit, to name a few. Some gin-lovers like a gin with a complex mix of botanicals. Others prefer a simpler approach that gives more prominence to the base spirit which has been used to make the gin. It’s all a matter of taste.

The traditional way to add botanicals to a gin is a process called steep and boil distillation. In this method, the juniper and any other desired botanicals are placed with the base spirit into a large vessel called a pot still. They are then left to stew for a period ranging from a few minutes to a few days, according to the distiller’s preference. The ingredients are then distilled together by boiling. This process extracts the essential oils from the botanicals and infuses them into the spirit.

Some distilleries flavour their gin using an alternative process known as vapour infusion. This is the method we use at Wild Knight Distillery to produce our Boadicea gin. The process involves placing the botanicals in baskets, above the base spirit within the still. The spirit is heated, which causes it to evaporate and rise as vapour. It then infuses with the botanicals, and finally condenses into a flavoured spirit.

Lowering the strength

After redistillation, we are left with a strongly flavoured, very strongly alcoholic distillate. This must be reduced down in alcoholic strength in order to make it safe and pleasant to consume. Typically, filtered water is added until the spirit reaches bottling strength, which usually means it has an alcohol content of about 40%. This process, usually concludes the gin-making journey.

Further steeping to make flavoured gin (optional)

If additional flavour is the goal, the distiller (or gin-drinker) may choose to add another flavour to a “finished” gin, through an additional phase of steeping with their chosen botanical.

Boadicea Gin ‘Rosa’ is steeped in cherries after distillation. Other botanicals commonly used in post-distillation steeping include strawberries, rhubarb, sloes, lavender and elderflower.

You can try flavouring a gin at home by combining a classic dry gin with your chosen botanical in a sterile, sealable container such as a Kilner jar. The ratio of gin to botanical should be 1 liter to 200-400g. Leave the container for a period of days to weeks (this varies depending on the botanical used), then sieve the gin and drink it at your leisure.

Bottling

The hugely satisfying final step of making gin, is bottling the spirit. Technically, any sterile, sealable bottle will suffice. In our distillery’s case, we like to push the boat out a bit, with a beautifully tall, elegant and attractively coloured bottle. Why go to all that effort learning how to make gin, if you’re not going to treat it like the special spirit it truly can be?

Featured collection

All are available with fast delivery throughout the UK mainland. For a gift, add a message during the checkout and we will include a personalised gift note for you.

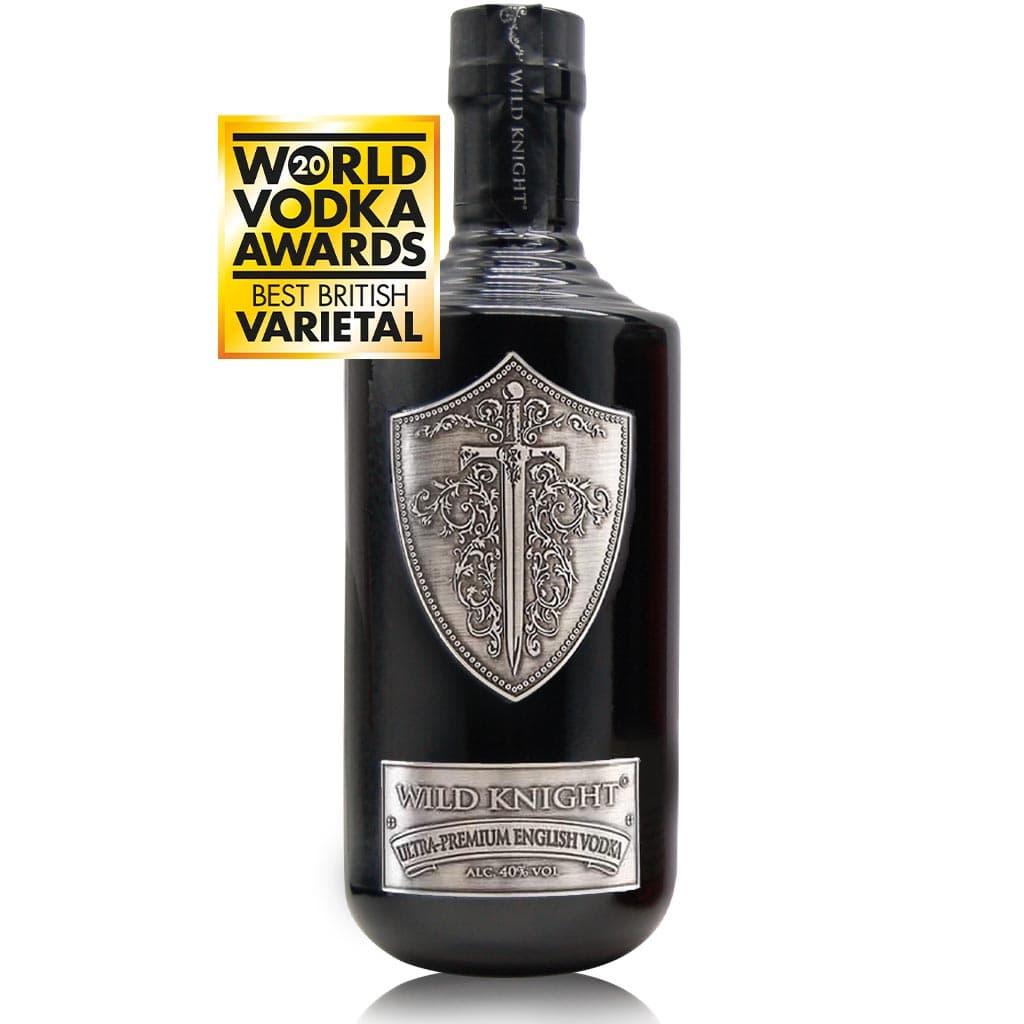

Wild Knight English Vodka is perfect sipped just over ice but there are a wide range of cocktail ideas here for you to try. From classics, to serves for the adventurous.

Nelson's Gold Caramel Vodka is one of our best-selling spirits. Most people will enjoy it neat over ice but we have a selection of suggestions to take Nelson's Gold that one step further.

There is a big world of serves outside of the G&T. Try something new today. We have plenty of ideas for you to taste.

Join Our Community

Be the first to know about new releases and gain access to exclusive information and offers.

We provide a 100% no-spam guarantee.