Add description, images, menus and links to your mega menu

A column with no settings can be used as a spacer

Link to your collections, sales and even external links

Add up to five columns

Add description, images, menus and links to your mega menu

A column with no settings can be used as a spacer

Link to your collections, sales and even external links

Add up to five columns

How Our Gin is Made

June 09, 2021

We are often asked how English gin is made? Or how to make gin? Well this is where I share with you how we make our Boadicea Gins.

Gin is a type of flavoured vodka. The base vodka spirit is the canvas onto which the gin maker can create their own flavour profile. We use botanicals such as fruits, berries, flowers, nuts and herbs to create aroma and flavour.

There are some different ways in which gin is made, but our process is vapour-infusion. We pass the alcohol vapour through botanicals within the column in our still, to collect flavour and aroma.

The picture below is our copper gin still. Copper is traditionally used for stills as it is an excellent conductor of heat. This allows a more even heating of the liquid and vapour in the still, resulting in a more constant product. Copper also helps to smooth the spirit and can remove unwanted flavours and aromas.

We create our Boadicea gins in batches. First we charge the pot of the still with our vodka and then create a bed of botanicals on a tray near the top of the column. The type and amount of botanicals varies according to the individual recipe.

We load the tray with each individual botanical added in the same order each time. This creates an even spread of botanicals and ensures that the alcohol vapour collects maximum flavour and aroma.

The image below is looking down the column to the botanical tray, loaded for our Boadicea Gin - Spiced. A bed of juniper has been covered with cranberry, coriander and a secret blend of spices to create our recipe.

The still is heated and held at a very low boil. The alcohol vapour travels up the column and through the bed of botanicals, collecting flavour and aroma along the way. The vapour is then condensed back down into a liquid again and collected. The alcohol strength at the collection point starts at about 88% ABV (Alcohol By Volume) and drops through the distillation run.

The distillation run takes approximately 10 to 12 hours. One of the skills is to adapt the still heating to account for the ambient temperature on the day. This can vary by 25 degrees Centigrade across the year.

If the still is too hot, the vapour runs faster and collects flavour differently. We are aiming for consistency run-to-run. One of the ways we do this is by balancing the heating, to achieve our target distillate collection speeds.

At the end of the gin distillation run, we lift the lid of the column to remove the botanicals from the still. The aroma that rises from the column is wonderful and reminiscent of hot summer nights, with heady fragrance hanging in the air.

The collected distillate is not yet ready to drink. During the distillation run, some of the flavour and aroma molecules are more soluble in alcohol and some are more soluble in water. We need to reduce the alcohol level down to bottle strength but that's a big drop from still strength down to bottle strength.

We have to add the reduction water gradually and in stages to remove any chance of the molecules precipitating out to form a cloudy spirit. The water that we use to reduce the alcoholic strength of the gin has been filtered and demineralised using a reverse osmosis process, resulting in a pure base for the gin.

Once we have proofed the gin to bottle strength we allow it to rest for a couple of weeks before final filtration and bottling.

And then its time to enjoy the finished spirit.

This is Biscuit (aka Dave) our distillery dog ready to go home after a long day. Or maybe ready for a walk, or a bone. Loves both!

Featured collection

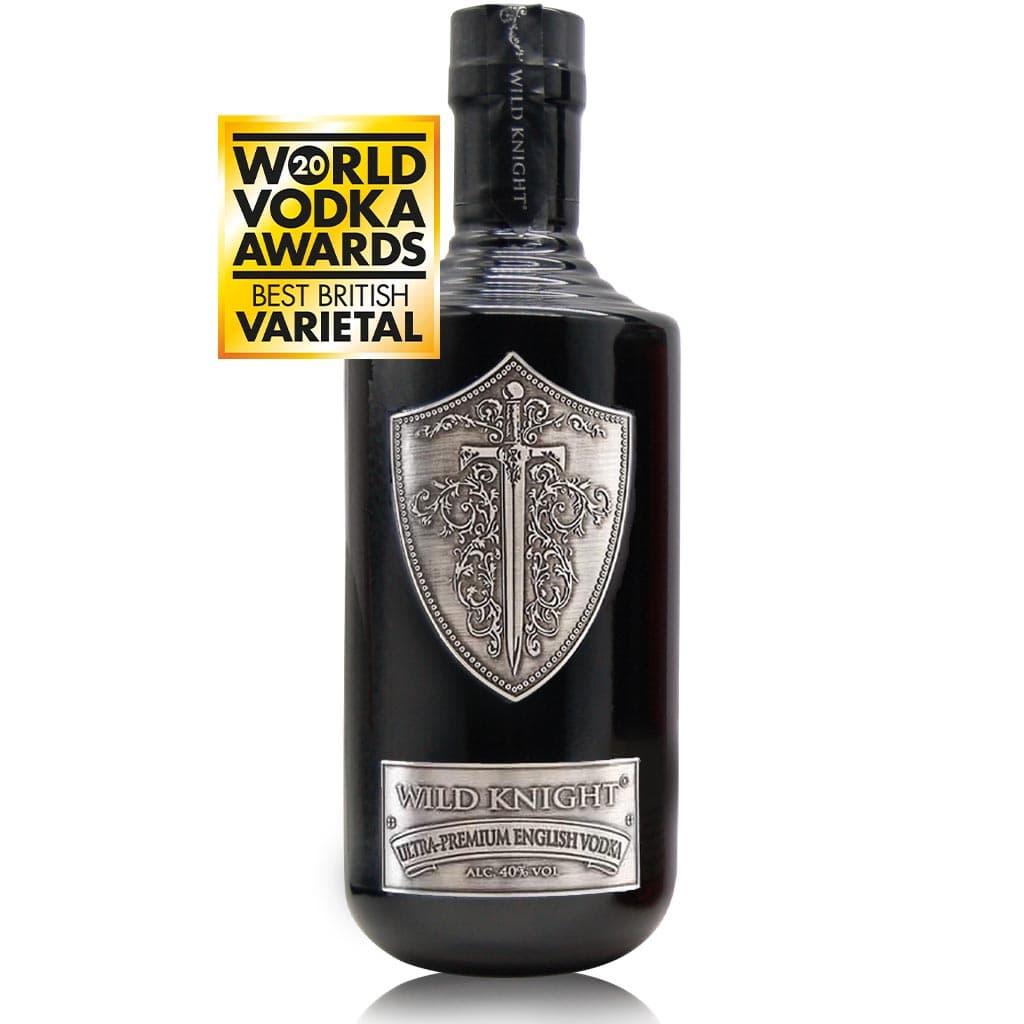

Wild Knight English Vodka is perfect sipped just over ice but there are a wide range of cocktail ideas here for you to try. From classics, to serves for the adventurous.

Nelson's Gold Caramel Vodka is one of our best-selling spirits. Most people will enjoy it neat over ice but we have a selection of suggestions to take Nelson's Gold that one step further.

There is a big world of serves outside of the G&T. Try something new today. We have plenty of ideas for you to taste.

Join Our Community

Be the first to know about new releases and gain access to exclusive information and offers.

We provide a 100% no-spam guarantee.